Build Report – Kyosho Inferno MP9

The Kyosho Inferno has a long and illustrious history in the 1:8 off-road scene. Through it’s various incarnations it has taken many titles from National right up to World Championship level. Here now we have the latest version, the MP9. Lets see how it goes together…

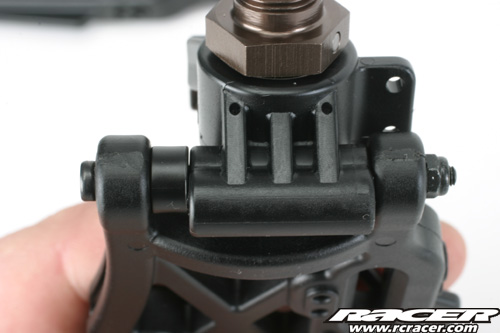

The build starts with the front, centre and rear differentials. All three use hardened steel outdrives and the cases include four smaller and two large bevel gears. Notice the centre differential (centre) has a larger casing and holds more fluid.

All the main drive gears for the diffs are hardened steel. Kyosho provide silicone diff fluid in the kit; 4000 for the front and centre, 2000 for the rear.

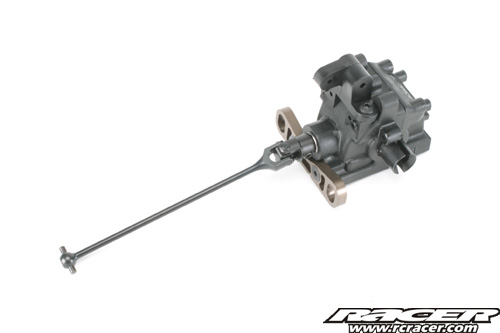

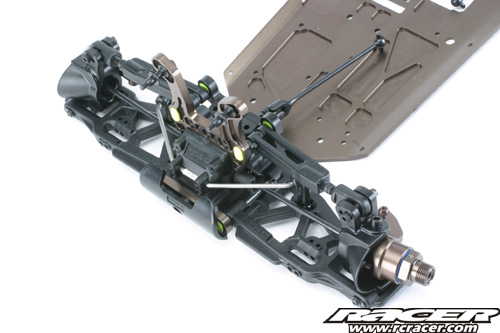

The rear gearbox is next to be built. The MP9 has a full compliment of UJ driveshafts, including those for the centre of the buggy.

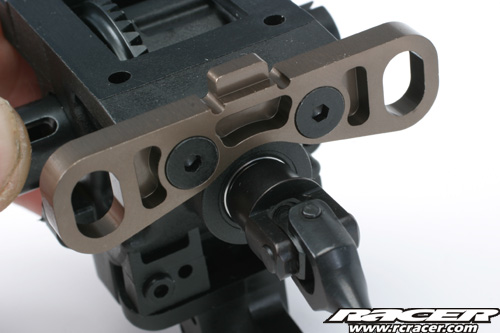

The forward inner rear hinge pin mount is machined alloy. There are inserts which locate the hinge pins to alter geometry.

Next to be added is the wing mount and rear shock tower. The tower is also machined alloy and has many alternative mounting holes for shock position and inner camber link position.

From there we move to the wishbones themselves. Substantial mouldings, the parts all fit together well without excessive play.

There is also an insert in the outer end of the wishbone enabling geometry changes here too.

Here you can see that wheelbase adjustments can be made thanks to a spacer between the hub and wishbone. Also note the use of hinge pins secured with locknuts.

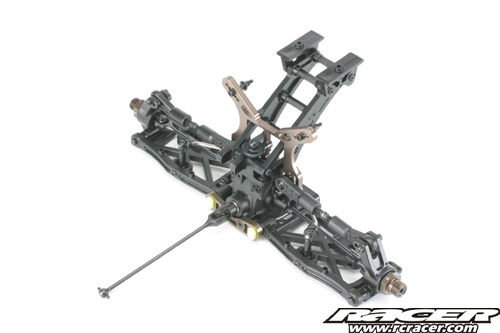

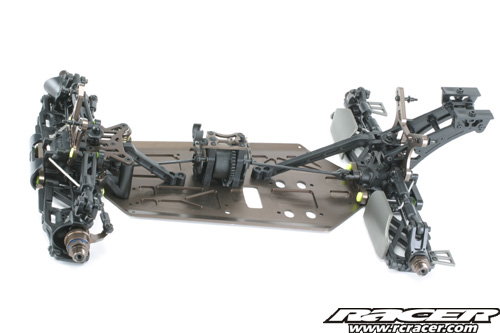

The completed rear end waiting for shocks and attachment to the chassis plate.

The rear pivot block on the back gearbox is plastic. Again it has an insert to change geometry which are flouro yellow. Although they function ok in this colour, they make the completed chassis look a bit lurid. Black inserts would have been better!

Anti-roll bars are supplied in the kit and a small heatshrink sleeve marking shows its size. Take care tightening the pinch screws so that the bar isn’t trapped.

The rear end attached to the chassis. Also notice the attachment of the dirt guards for the rear wishbones and the rear wheel scrapers on the rear of the hubs. These plastic parts are all stock equipment in the kit.

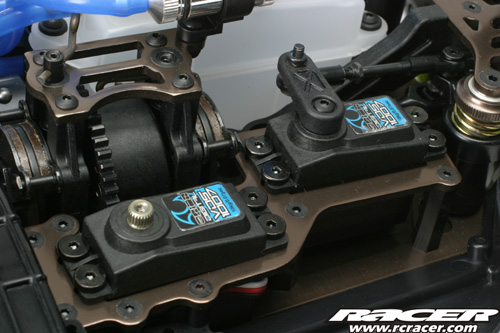

The chassis is very nicely milled out in areas to save weight and also in places such as under the servos to lower these parts.

Moving to the front, you can see here the insert which goes into the front C-hub. This alters the castor without any additional parts.

The front hubs are machined alloy for strength. The axle bearings also sit in a plastic insert which is the blue part that can be seen here. This lessens shocks on the bearings, leading to longer life.

The rest of the front end is pretty standard fare and goes together easily. Some more of those horrible flouro yellow geometry inserts spoil the quality look though..why kyosho, why…

A couple more views of the front end. The top link design uses an upper wishbone while alloy is again the material of choice for the hinge pin holders.

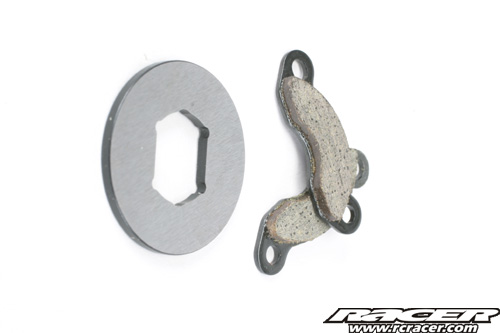

The brakes have laser cut discs which are beautifully finished. The pads also come with their friction material bonded to the backing plates.

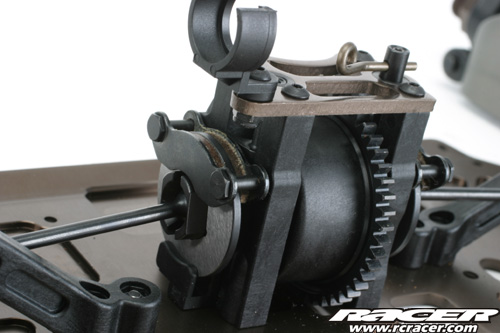

The centre differential in place. The MP9 uses a twin disc setup, one on each output on the centre diff. Notice also the two plastic chassis braces which go to the front and rear gearboxes.

The servo saver comes pre-built in the kit and the aluminium steering drag link has a choice of ackermann positions. Both bellcranks are ballraced and the linkages are steel turnbuckles.

The major mechanicals on the chassis. Building the MP9 is hard on the hands as the combination of hard plastic and machine screws makes for blisters…

Kyosho provide a three-shoe clutch in the MP9 kit. It comes complete with alloy shoes and uses standard 5x10mm clutch bell bearings.

The finned alloy engine mounts easily accomodated our Team Orion engine.

Clearance is tight though with the engine in place. The instructions said we may have to grind away a small amount of the engine mounting to clear the centre shaft. They wern’t lying…

Team Orion’s latest digital servos were used in out MP9 build, fitting easily and needing no spacing up on the aluminium radio plate to clear the chassis.

The radio box has hinged lids and plenty of room to accomodate the receiver pack and Spektrum receiver. We also added some foam packing here to help protect the radio components.

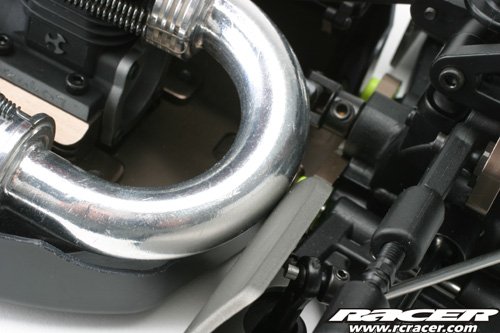

Clearance between the manifold and dirt guard is tight, we’ll see how this pans out in testing. The dirt guard may need trimming to avoid the manifold, only time will tell.

The fuel tank includes a neat little handle to aid speedy refuelling. A nice inclusion in the kit.

Moving to the shocks, two different pistons are provided in the kit. On Kyosho UK’s recommendation, we went for Black 1.2mm hole pistons in the front end coupled with 40wt oil and White 1.3mm pistons in the rear, squidging 35wt fluid.

The big-bore shocks are the last major stage of the build bar the body wheels, tyres and wing attachment. The shock seals are retained by a circlip and the shafts protected by rubber boots.

The body was painted up and decalled and a set of AKA IBeams fitted to a set of Kyosho rims. The body is very nice and sleek, absent of many of the lumps and bumps that seem to be on some buggies for clearance of parts underneath.

So what do we think the? Well on the basis of how it goes together, it should be a winner. Kyosho have now got competitive on pricing too and although the MP9 could in no way be classed at revolutionary for the 1:8 off-road class, it is an evolution and puts into practice Kyosho’s testing without taking any big risks. Read our full review in RC Car Racer magazine soon and also check back here on the website too when we report back after giving our MP9 a sound thrashing at the Westmill track with the guys from Kyosho UK.

More Information: Kyosho Europe