How To Mount Brushless Systems

Affordable brushless motors and electronic speed controls have been around for quite a while now. This makes more and more drivers upgrade from conventional brushed motors to the brush and commutator-less motors. Unfortunately most of the current brushless speedos are quite bulky which is as, generally speaking, one brushless speed control combines three conventional speedos.

During the last couple of years the size of brushless speedos has begun to shrink but many of the budget offerings still need plenty of room on the chassis. This means you have to think for a minute or two of where to put all needed components like the steering servo, receiver, speedo and additional capacitors if needed. The steering servo position is not change-able in most cars so it’s down to the speed controller and receiver to be fiddled into the tightness of today’s on and off-road chassis.

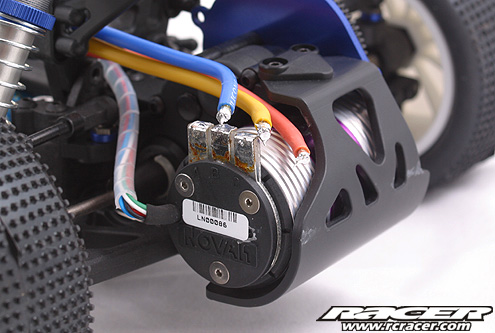

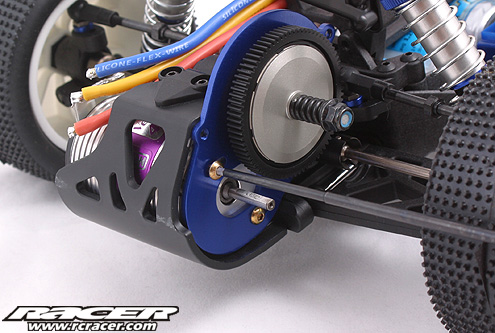

First up mount the motor on the dedicated motor holder. Use the forward-mostposition possible to make sure the motor does not interfere with the other components in case you are forced to use large pinions or main gears.

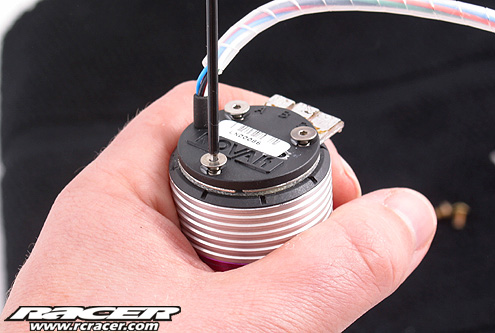

If you lare using an already used speedo or a new one without any wires on it make sure the wires are damage free and long enough to reach the motor solder tabs and the battery plugs.

Dry-fit the speedo to make sure all wires are of the needed length. Replace those that are too short with new ones.

Ensured everything is of the needed length it’s time to clean the bottom of the speedo casing with motor cleaner before applying double sided foam tape.

Put the speedo in place leaving some space for the wires and sensor cable.

If the sensor cable is too long, bundle it with cable ties, shrink wrap or insulating tape. Make sure not to crimp the cables too much!

Now solder the power cables on the motor tabs or add plugs if the design of the motor allows for them. Make sure you use short wires to keep performance losses to a minimum.

Now place the capacitor in a sensible place as far away from the receiver as possible, route the receiver cable and mount the on/off switch on a place where is can’t be knocked during running.

you talk of the whiring but onley show a motor strip down and clean in the picturs?