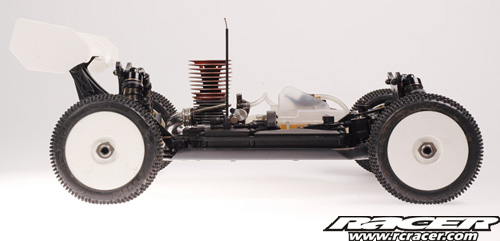

Serpent 1:8 Buggy Project With Billy Easton – Part Three

Here is the third of four interviews with Billy Easton the designer / racer of the Serpent 1:8 buggy. The Serpent 1:8 buggy is the first move into the off-road market, to be followed by a Truggy and electric versions, as well as Ready To Race cars in the near future. Design-wise Billy Easton works closely together with Michael Salven. With Michael being the expert in gas on-road, Billy will perform this task for the off-road projects. In this way true experts look after the class they know best and actively race in and can support best whilst still sharing idea’s and knowledge to create the very best RC racing cars around.

Can you advice us the final name for the car:

Yes , the car is named Serpent S811 Cobra . As you can also see from the images of the logo. It makes a small hint to the off-road history of Serpent.

It’s time for some more details about the Serpent Cobra. Can you give us some idea on the following areas:

Geometry

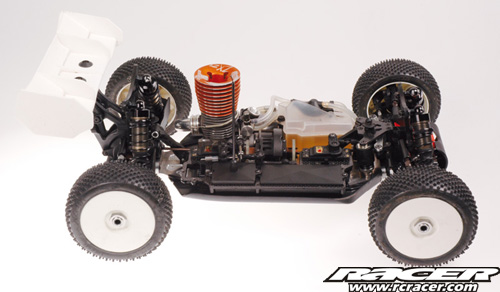

The geometry is actually well proven. With over 15 different manufacturers tested and countless hours of driving, so many different concepts and suspension styles have been taken into account, the customer will indeed be happy with the package we put together for them. The geometry is set up for maximum performance with the most efficient cornering in mind. Utilising proven roll centres, shock progression and camber links, it’s a given winner.

Weight balance

The weight balance is some of the best that I have ever experienced. The front to back and left to right balance have been greatly enhanced over even some of the most recent buggies. The customers will definitely not find one side of this vehicle dragging the ground over another. It is perfect and it is barely if at all affected by the different types of batteries you can use.

Gear Ratios

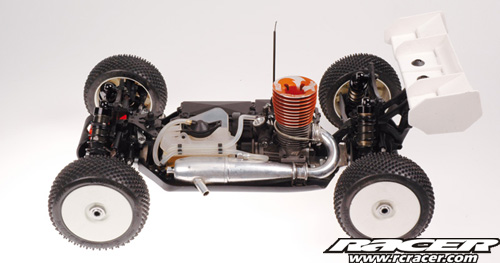

The gear ratio in our buggy is 4.3:1. This has been proven to give you the most possible acceleration and also allow you to use a much larger variety of clutch bells. I would hate to see a guy never be able to gear his car down on a short track if he needed to if it meant the difference between winning and losing.

Suspension / Shocks

The suspension is comprised of suspension arms that are very similar in length and also should aid in cornering as well as rough track handling. We took some of the oldest design concepts and updated them for competition in 2010. As for the shocks they are 16mm big bores, so you can jump land even the largest jumps on the US style tracks. These shocks will definitely minimise oil overheat and aid in long mains.

Engine Related

The engine’s location has been maximised to allow you just the right adjustability without compromising any of the cars overall balance. It is a forward type similar to those on recent cars, but not exaggerated too far to any extreme.

Clutch

The clutch itself is a four-shoe. After lots of testing different types of clutches it was decided that the four-shoe was the best overall choice. With the ability to change shoes evenly carbon verses aluminium as well as utilising the simplest building concept, I think the customers will be very happy with the end clutch design. You will be able to run different combinations of clutch shoes, but also be able to build multiple units to change out quickly.

Steering System

Our steering system is actually a more advanced system than you may have seen till now. We utilise a bell crank system that is angled to better match the caster angle. What this means to you, is less bump steer than you have ever experienced before. Our turnbuckle length is also improved over other buggies to again reduce unwanted bump steer. The overall package is very simple in design, user friendly and easy to adjust.

Lots more to follow in the next and last of this series of interviews. More details on the Serpent S811 will be shown after the last of the interviews.

Source: Serpent